|

"WELCOME to my RC Project." |

|||

|

|

I'm an old model builder from way back. I began building back in the 70's, crash most of the planes I flew. Didn't have much money then so what I had wasn't all that great. I enjoyed flying but lets face it this is a adults sport, you need money to do it right. I decided to get back in it now that I'm a lot more solvent. |

||

|

|

|||

|

General Info Kits include all assembly hardware plus heavy duty landing gear and materials for a bolt-on or rubber band-attached wing. Larger, extra-stable PT-40 MKII takes a .40 engine - a size the pilot could likely reuse in future models. Ideal for small flying sites, PT-20 MKII also lowers startup costs by using an economical.20-size engine. Innovative "interlocking I-beam" engineering simplifies wing construction and maximizes strength. The ribs plug securely into spars and webbing to maintain proper alignment. PT wings are built with ailerons for full 4-channel control, but they can be locked in place for 3-channel operation. Leading and trailing edges come pre-shaped for easy assembly. Optional Trim Scheme Packages simplify covering [ Check out reviews by R/C Report & R/C Modeler Magazine ] |

PT-40 MKII

Stock Number: GPMA0118 Wingspan: 60 in (1520mm) Wing Area: 672 sq in (43.3 dm2) Weight: 5-6 lb (2270-2720g) Wing Loading: 17-21 oz/sq ft (52-64 g/dm2) Fuselage Length: 52.5 in (1335mm) Requires: 2-stroke .35-.46 cu in (5.5-7.5cc) or 4-stroke .40-.52 cu in (6.5-8.5cc) engine & 3-4 channel radio with 3-4 servos & 2+ rolls of MonoKote Parts Listing - Accessories Needed - Product Manual v1.2 |

||

| I began by ordering a set a plans I found in a magazine. I ordered a set of planes for a "Bristol M1" I ordered some balsa and basswood and began building. Since it was the dead of winter I wasn't much of hurry to get anything finished. The plane took on a life of its own. I worked on the cockpit. then a friend gave me a copy of a CAD program. That was it I was off the edge. I scanned the planes into my computer, relocated the cockpit five times, built four different ones and fitted them on the plane. I finally settled on the a look more like the H-1, Howard Hughes' speed plane. I still need trainer type wing on it so I read about ailerons and selected one with a flat bottom. I drew out the parts, cut them out with my band saw and glued them with carpenters glue. A friend intruded me to CA, WOW!!!! Below are a few pixs of that plane, as of yet unfinished. The cowling is from a corsair and the tail section is also of my design. I'm currently working on wheel pants taking the look of the GeeBee racer type. I currently have a 1.2 OS engine which i plan to use. Anyway its a far from finished, one of those forever projects. | |||

|

I'll do a page on this plane as time will allow. | ||

|

But on with the PT-40 project. I chose the 40 version just because I like big. I would love to of built the 60 but first it is time to get in the air before winter sets in and I wanted to learn more of modern building techniques. I have to learn to build cleaner, tighter. this ill be a good project to do that. |

|||

| First off I'd like to say the box came in the mail in very good shape and quickly from Tower Hobbies. The price was good at 70$. I opened the box and found all the wood packaged neatly and rubber banded nicely. The kit came with a black and white manual with good explanations of assembly and even a section on glues and tools. Even explained the different types of woods being used. I read the manual and began with the stabilizer. <top> | |||

|

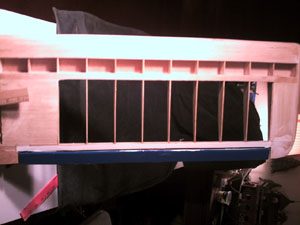

I read a few reviews that made reference to the fact, that the PT-40 is a bit tail heavy. I decided to build what was supplied, but then just for fun I built an open form stabilizer. I added elevator stock and nylon hinges. | ||

|

|

|||